Aluminum alloy Plate

The thickness of the aluminum plate is more than 0.2mm, 500mm or less, 200mm width or more, the length of 16m or less of aluminum called aluminum plate or aluminum sheet, 0.2mm or less for aluminum, a width of less than 200mm or discharge material strip (of course with the advancement of large equipment, the widest 600mm exhaust timber can be done will be more). Refers to the processing of aluminum ingots rolled rectangular plate, divided into pure aluminum, aluminum alloy, thin aluminum, aluminum pattern in the thick aluminum,aluminum checker plate.

Typical Aluminum alloy

|

|

|

|

| 5083 aluminum plate | 6061 aluminum plate | 5086 aluminum plate | 5052 aluminum plate |

|

|

|

|

| 2024 aluminum plate | 7075 aluminum plate | marine aluminum plate | aluminum mold plate |

The advantages of Aluminum alloy Plate

Fine machinability

Comparing to the steel, the speed of aluminium alloy’s machinability is 4 times faster. Therefore, the mould manufacturing period can be shortened by using aluminium alloy material. Besides, the excellent machinability can largely reduce wear of cutting tools and extend their life, thus reduce the production cost and material waste.

Low density

With desity of 2700kg/m3, only 1/3 density of steel, the aluminium plate can be easily moved and transported, and the aluminium mould could be conveniently open and close because of low weight.

Outstanding thermal conductivity

With thermal conductivity 123W/m·K-170W/m·K, 4 times of the steel, aluminium alloy can shorten components cooling time effectively.

Aluminum Plate Typical Applications

Moulding industry, alloy 2xxx, 5xxx, 6xxx, 7xxx -Foam Moulding -Vacuum Forming -Blow Moulding -RIM and Structural Foam Moulding -Rubber Moulding -Injection Moulding

Pressure vessel industry, alloy 1xxx, 3xxx

Ship building industry, alloy 5xxx, 6xxx

Vehicles industry, alloy 5xxx

Machinery industry, alloy 5xxx, 6xxx, 7xxx

Production Process

Melting → Casting → Saw cutting → Slab milling → Hot rolling → Cutting → Inspection → Packing → Shipment

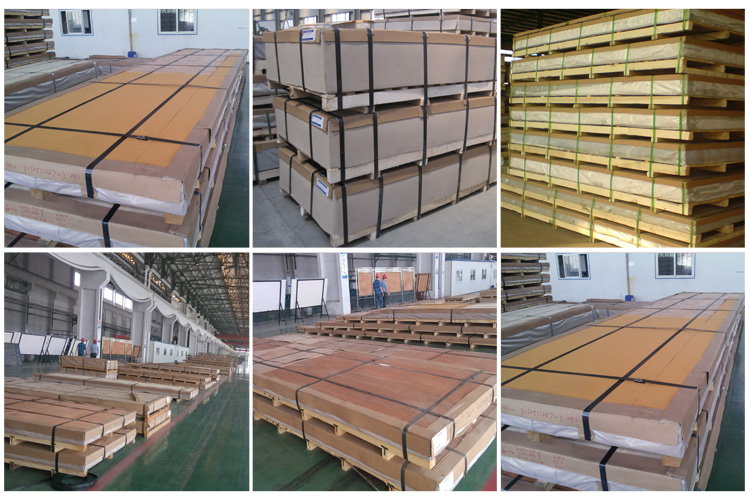

Packing

Haomei Aluminum Plate-We would like to highlight our aluminum plate,aluminum alloy plate 5083 aluminum plate,7075 t6 aluminum plate,aluminum 6061 plate,5086 aluminum plate,marine aluminum plate and aluminum mold plate with good quality and competitive price.we offers a wide range of aluminum Plate alloys for various applications.

Haomei Aluminum Plate-We would like to highlight our aluminum plate,aluminum alloy plate 5083 aluminum plate,7075 t6 aluminum plate,aluminum 6061 plate,5086 aluminum plate,marine aluminum plate and aluminum mold plate with good quality and competitive price.we offers a wide range of aluminum Plate alloys for various applications.